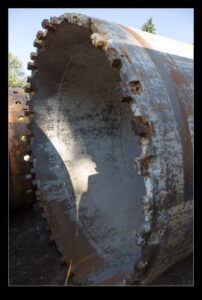

I was doing a visit to one of the construction sites that our team at work is managing currently. There is a lot of elevated guideway as part of this project and that involves drilling shafts for the elevated structures. The drilling was not underway at the location we stopped off at so I could see some of the drilling equipment. Not only was the auger like drill on site but also the cylinders with cutting heads mounted on the edge which are rotated in place by the other tool next to the drill. The crews can drill these holes at quite a rate when they are going and the result is that the structures are springing up across the project at this point. Nice to be part of something that will be soon serving the communities in the south part of King County.

I was doing a visit to one of the construction sites that our team at work is managing currently. There is a lot of elevated guideway as part of this project and that involves drilling shafts for the elevated structures. The drilling was not underway at the location we stopped off at so I could see some of the drilling equipment. Not only was the auger like drill on site but also the cylinders with cutting heads mounted on the edge which are rotated in place by the other tool next to the drill. The crews can drill these holes at quite a rate when they are going and the result is that the structures are springing up across the project at this point. Nice to be part of something that will be soon serving the communities in the south part of King County.

Tag Archives: drill

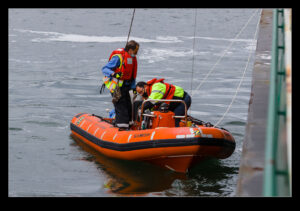

Rescue Boat Drills for WSF

On our most recent trip to Orcas, we had an unusual experience during the ferry crossing to the islands. The crew announced that there would be a rescue boat drill and that we weren’t to worry or do anything. The ferry came to a halt in the open water and the crew manned up the RIB. Fortunately, the RIB they were using was the one mounted on the side of the ferry we were parked on so I was able to lean out through the opening of the car deck and watch the launch.

On our most recent trip to Orcas, we had an unusual experience during the ferry crossing to the islands. The crew announced that there would be a rescue boat drill and that we weren’t to worry or do anything. The ferry came to a halt in the open water and the crew manned up the RIB. Fortunately, the RIB they were using was the one mounted on the side of the ferry we were parked on so I was able to lean out through the opening of the car deck and watch the launch.

Two crew members got in the boat and then the davit was swung out and the boat lowered to the surface. They got the motor going, let out the lines and zipped off in to the distance. I figured they would shortly be back but they seemed to go quite a way off and then disappear from view. Instead, the ferry powered up and continued on its way.

Two crew members got in the boat and then the davit was swung out and the boat lowered to the surface. They got the motor going, let out the lines and zipped off in to the distance. I figured they would shortly be back but they seemed to go quite a way off and then disappear from view. Instead, the ferry powered up and continued on its way.

As we got closer to our first stop at Lopez, we caught up with the RIB and, after bringing the ferry to a stop again, the process was reversed and the boat was brought back on board before we resumed our normal crossing. Reading the Washington State Ferries news emails, it appears that rescues are a pretty regular feature with the ferries picking up various water users that have got themselves in to trouble. Good that they keep well practiced!

As we got closer to our first stop at Lopez, we caught up with the RIB and, after bringing the ferry to a stop again, the process was reversed and the boat was brought back on board before we resumed our normal crossing. Reading the Washington State Ferries news emails, it appears that rescues are a pretty regular feature with the ferries picking up various water users that have got themselves in to trouble. Good that they keep well practiced!

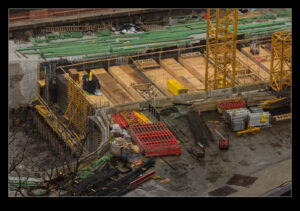

Foundations for a Tall Building

I have already posted a couple of times about the construction next to our old apartment in Chicago. The demolition of the Sun Times building was here and the removal and replacement of Wabash Avenue was here. This was all associated with the construction of the new tower. Since the plot on which this tower was going to be built was pretty small, it couldn’t be a traditional steel frame skyscraper. The provide the stiffness needed for such a slender tower, it had to be constructed of concrete.

I have already posted a couple of times about the construction next to our old apartment in Chicago. The demolition of the Sun Times building was here and the removal and replacement of Wabash Avenue was here. This was all associated with the construction of the new tower. Since the plot on which this tower was going to be built was pretty small, it couldn’t be a traditional steel frame skyscraper. The provide the stiffness needed for such a slender tower, it had to be constructed of concrete.

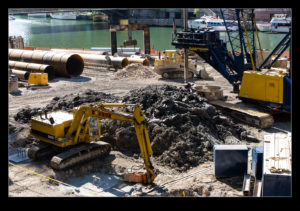

This required a substantial foundation. First was the need to clear out the old foundations. The Sun Times building had been constructed on top of a ton of piles that were timber poles driven in to the ground. These all had to come out before anything else could be done. Tons of them would be lying around at various times as they were pulled out prior to being taken away.

This required a substantial foundation. First was the need to clear out the old foundations. The Sun Times building had been constructed on top of a ton of piles that were timber poles driven in to the ground. These all had to come out before anything else could be done. Tons of them would be lying around at various times as they were pulled out prior to being taken away.

Next was the need to drill down for the new piles. I seem to recall that they went down about 130 feet but my memory may be off on that. Some of the piles were really wide while others were slightly narrower. Larger drills would take out the earth and then steels cylinders would be inserted in to the whole. Rebar reinforcements would be inserted before the concrete could be poured in to make the final pile. This process was repeated across the site over a course of months.

Next was the need to drill down for the new piles. I seem to recall that they went down about 130 feet but my memory may be off on that. Some of the piles were really wide while others were slightly narrower. Larger drills would take out the earth and then steels cylinders would be inserted in to the whole. Rebar reinforcements would be inserted before the concrete could be poured in to make the final pile. This process was repeated across the site over a course of months.

All of this was the precursor to the main foundation. The building was built on top of a concrete raft. This sat on top of all of the piles. It was a single pour. The whole pour took about 48 hours. A steady stream of trucks brought the concrete in from a mixing plant a couple of miles away. The mix was a special high strength one and each truck was tested as it arrived. Pouring such a volume of concrete continuously required great care because the material generates heat as it sets and there was constant monitoring to ensure that the overall temperature remained within range. Once they started, they couldn’t stop.

All of this was the precursor to the main foundation. The building was built on top of a concrete raft. This sat on top of all of the piles. It was a single pour. The whole pour took about 48 hours. A steady stream of trucks brought the concrete in from a mixing plant a couple of miles away. The mix was a special high strength one and each truck was tested as it arrived. Pouring such a volume of concrete continuously required great care because the material generates heat as it sets and there was constant monitoring to ensure that the overall temperature remained within range. Once they started, they couldn’t stop.

The whole thing apparently went to plan and the result was a large concrete base on which the rest of the construction effort would build. After months of preparation, finally it was time for things to start going up again.

The whole thing apparently went to plan and the result was a large concrete base on which the rest of the construction effort would build. After months of preparation, finally it was time for things to start going up again.