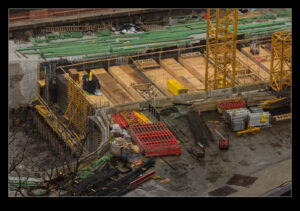

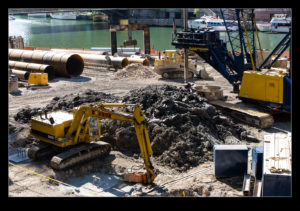

WSDOT is in the process of building a new part of SR509 that will connect I-5 to the rest of SR509 on the west side of the airport. The alignment that the new road is taking cross SR99 at the same place that we are currently building the light rail extension. To avoid making life too complex, WSDOT funded Sound Transit to build the bridge for SR99 that is needs as part of the light rail construction program. The contractor diverted SR99 around the work site and then excavated the area where SR509 will go. A new bridge was built over this and then it was all filled in underneath. The road then was laid on top of the new bridge.

WSDOT is in the process of building a new part of SR509 that will connect I-5 to the rest of SR509 on the west side of the airport. The alignment that the new road is taking cross SR99 at the same place that we are currently building the light rail extension. To avoid making life too complex, WSDOT funded Sound Transit to build the bridge for SR99 that is needs as part of the light rail construction program. The contractor diverted SR99 around the work site and then excavated the area where SR509 will go. A new bridge was built over this and then it was all filled in underneath. The road then was laid on top of the new bridge.

Since these pictures were taken, the road has been re-opened. However, at this tie, they were finishing the pours of concrete for the new bridge and too tie it in to the existing roadway. This view is now gone so it was a narrow window to see the bridge. I was lucky to see it at various stages of its construction. In due course, WSDOT’s contractor will come in and remove the earth under the bridge and build the SR509 roadway. That will happen pretty soon.

Since these pictures were taken, the road has been re-opened. However, at this tie, they were finishing the pours of concrete for the new bridge and too tie it in to the existing roadway. This view is now gone so it was a narrow window to see the bridge. I was lucky to see it at various stages of its construction. In due course, WSDOT’s contractor will come in and remove the earth under the bridge and build the SR509 roadway. That will happen pretty soon.