Today we have a bit of a flashback. Regular readers will know that I shoot a lot of helicopter operations. Midwest Helicopters is the large local operator so they do most of the work in the city. However, there other operators that undertake similar work and some of them will work in Chicago at times. This is often a function of the weight of the loads to be lifted. Construction Helicopters of Howell MI are one such operator and their S-61N aircraft can lift 10,000lbs – a big increase over the 4,500lbs of the S-58T. If you need even bigger things lifted, Erickson Aircrane are probably your people!

Today we have a bit of a flashback. Regular readers will know that I shoot a lot of helicopter operations. Midwest Helicopters is the large local operator so they do most of the work in the city. However, there other operators that undertake similar work and some of them will work in Chicago at times. This is often a function of the weight of the loads to be lifted. Construction Helicopters of Howell MI are one such operator and their S-61N aircraft can lift 10,000lbs – a big increase over the 4,500lbs of the S-58T. If you need even bigger things lifted, Erickson Aircrane are probably your people!

This piece, though, is not about the helicopter so much as the people it was working with. A few years ago, the Trump International Hotel and Tower was built here in the city – in fact just across the street from us. We had the best seats to watch the demolition of the old Sun Times building and the growth from a hole in the ground to 92 floors of building. It was fun to watch, even if it did take a chunk out of our view! The building was topped off with a spire. The parts for the spire were lifted to the roof by the construction cranes before they were assembled but it was going to be significantly higher than the rest of the building so those cranes were not suitable for assembling it. The pieces would be lifted into place by helicopter.

This piece, though, is not about the helicopter so much as the people it was working with. A few years ago, the Trump International Hotel and Tower was built here in the city – in fact just across the street from us. We had the best seats to watch the demolition of the old Sun Times building and the growth from a hole in the ground to 92 floors of building. It was fun to watch, even if it did take a chunk out of our view! The building was topped off with a spire. The parts for the spire were lifted to the roof by the construction cranes before they were assembled but it was going to be significantly higher than the rest of the building so those cranes were not suitable for assembling it. The pieces would be lifted into place by helicopter.

The first attempt at this was unsuccessful as the winds were so strong that keeping each piece in place long enough to secure it proved impossible. There was a long wait before the second attempt but the job finally went ahead. The heroes of this story are the guys on the tower. If you think that the tower itself is over a 1,000′ tall and the spire is a significant (and flexible) structure above that, you can see that this is quite an exposed location to be working. From talking to the team that assembled it, the most senior guys are the ones at the very top – they want to be there.

Three guys were on the spire at the top. As each section was brought into place, they grabbed the tag lines and pulled it into position. When they had located it, they would put in a bolt in each corner. Then, one would climb up the new piece to release the lifting line. The other two would follow while a second group came behind them to insert the additional bolts to finally secure the section. While they were finishing that off, the next piece was coming in.

To add to the fun of this, the spire narrows as it gets higher so the working space gets progressively more limited. All the time you are dealing with whatever wind conditions there are at this height combined with the not inconsiderable down-wash from the helicopter and trying to make sure you maintain your grip and don’t drop anything on the team below you!

The job ran a little long but they did finish it off and put the final cap in place. They seemed to do a great job but were so far away from anyone else, I suspect that very few people appreciate exactly what they had done. It was only recently as I was culling a bunch of old images that I looked again at them as saw exactly what they were doing. I feel guilty for paying more attention to the helicopter operations when I first shot the job so decided to give them a little publicity now. Well done everyone.

The job ran a little long but they did finish it off and put the final cap in place. They seemed to do a great job but were so far away from anyone else, I suspect that very few people appreciate exactly what they had done. It was only recently as I was culling a bunch of old images that I looked again at them as saw exactly what they were doing. I feel guilty for paying more attention to the helicopter operations when I first shot the job so decided to give them a little publicity now. Well done everyone.

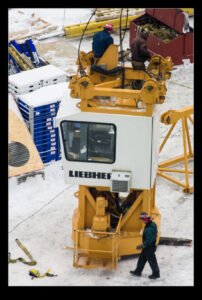

A hangar has been under construction at Paine Field for a while and, while so much time has been taken up by the preparation of the groundwork, I happened to be there when they were assembling the frame of the hangar. The long span that the finished structure will have is built up of two pieces with the side beams and the roof beams for one side being assembled on the ground and then two cranes being called in to lift both halves up simultaneously so that they can be bolted in the center to provide the rigidity needed.

A hangar has been under construction at Paine Field for a while and, while so much time has been taken up by the preparation of the groundwork, I happened to be there when they were assembling the frame of the hangar. The long span that the finished structure will have is built up of two pieces with the side beams and the roof beams for one side being assembled on the ground and then two cranes being called in to lift both halves up simultaneously so that they can be bolted in the center to provide the rigidity needed. Seeing the cranes holding these large frames in place and the crews using scissor lifts to get up to put the connections in place was quite neat. Once the frames are in place, the process of cladding the building can take place in slower time. Those cranes will have been expensive to rent so getting that heavy lifting done as fast as possible will have been the goal.

Seeing the cranes holding these large frames in place and the crews using scissor lifts to get up to put the connections in place was quite neat. Once the frames are in place, the process of cladding the building can take place in slower time. Those cranes will have been expensive to rent so getting that heavy lifting done as fast as possible will have been the goal.