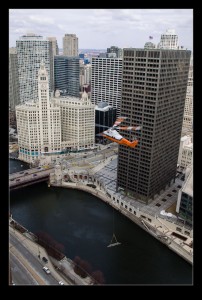

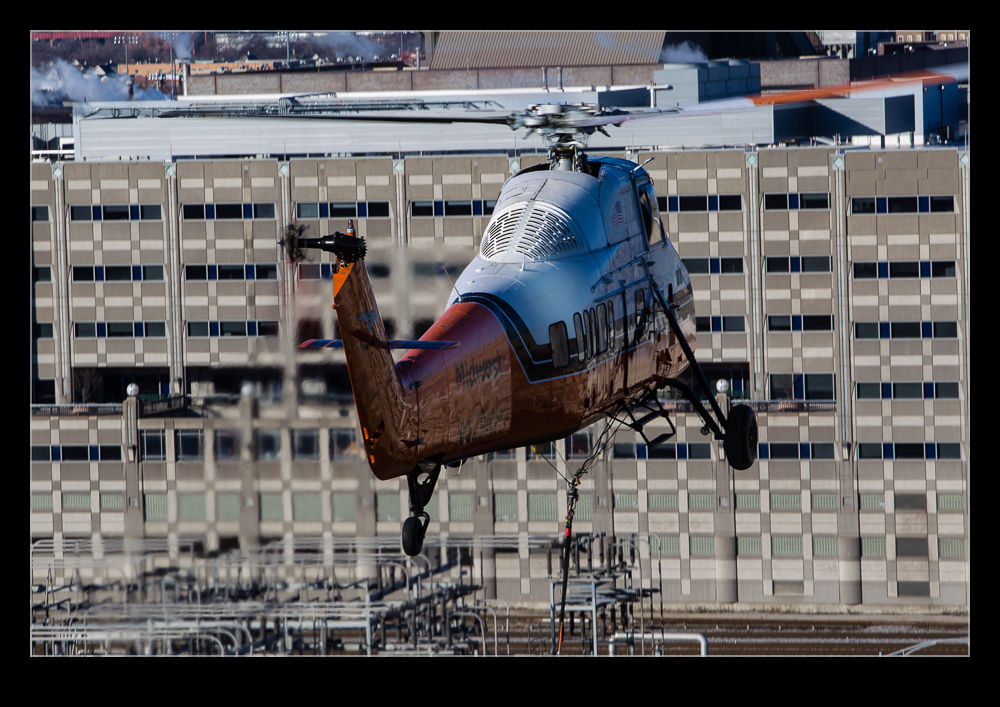

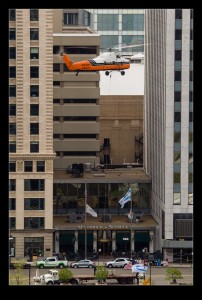

I know what you are thinking. It has been a long time and no helicopter photos Rob! You are right, it has been too long. Fortunately, I can rectify the situation. The good people at Midwest Helicopters had a very intensive project recently. The Merchandise Mart in Chicago was the project in question. They are installing a series of new chiller units on the roof of the building. These are big units – too large for the Midwest helicopters to lift as it happens. However, before they go up, there is plenty of work to be done.

I know what you are thinking. It has been a long time and no helicopter photos Rob! You are right, it has been too long. Fortunately, I can rectify the situation. The good people at Midwest Helicopters had a very intensive project recently. The Merchandise Mart in Chicago was the project in question. They are installing a series of new chiller units on the roof of the building. These are big units – too large for the Midwest helicopters to lift as it happens. However, before they go up, there is plenty of work to be done.

Big chiller units need to be mounted to something and getting the structural steelwork up on the roof is no small task. It needed over 180 lifts to complete the job. It was planned for two possible days with the whole day being booked for each occasion to maximize what could be done. Flying the helicopter all day was intensive for the aircraft and required two pilots to alternate in order to avoid getting exhausted.

Big chiller units need to be mounted to something and getting the structural steelwork up on the roof is no small task. It needed over 180 lifts to complete the job. It was planned for two possible days with the whole day being booked for each occasion to maximize what could be done. Flying the helicopter all day was intensive for the aircraft and required two pilots to alternate in order to avoid getting exhausted.

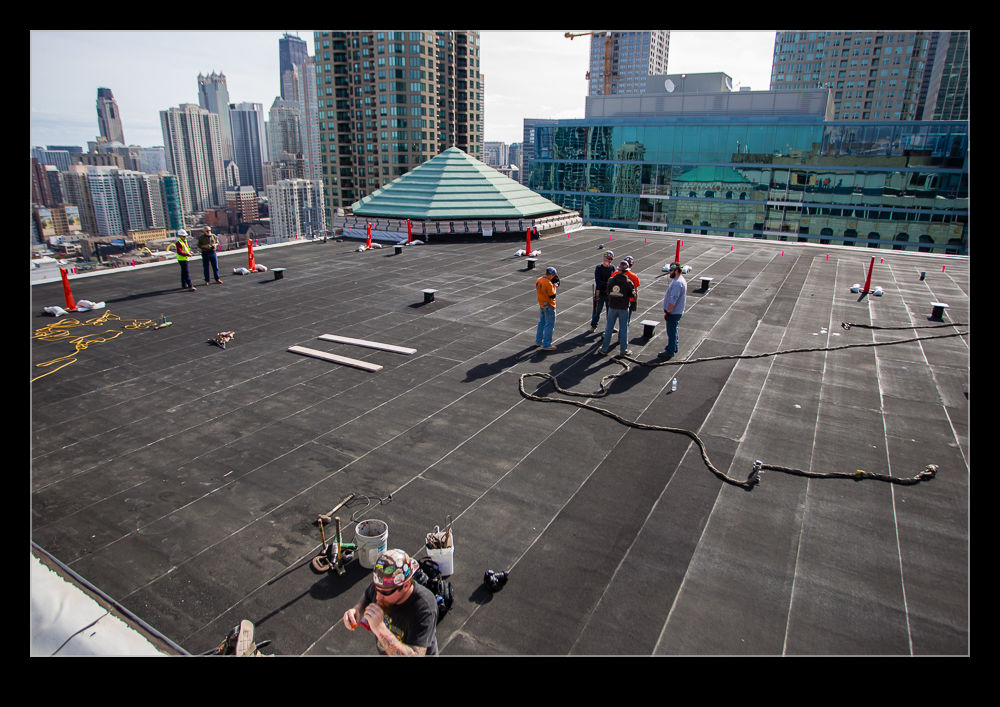

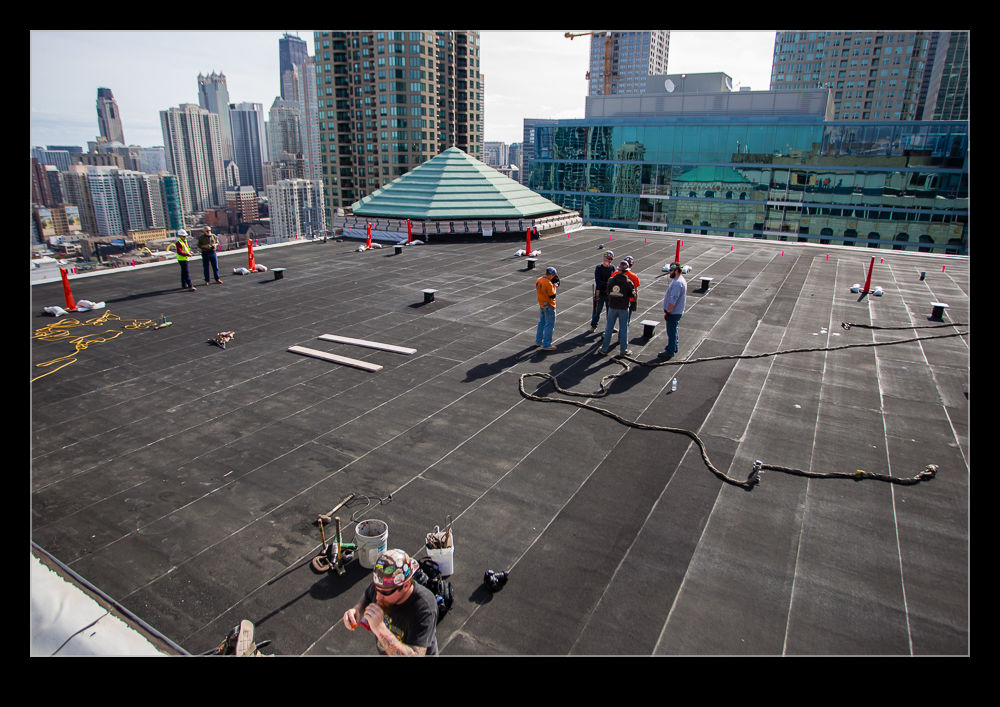

I got myself up on to the roof of the Mart for the job. The Mart is a huge building. It used to be the largest floor space building in the world before the Pentagon was built. It might still be second (and, if I was diligent, I could probably look that up to confirm it but we know that isn’t happening while I am in mid-story). The roof is a big space and there were two separate areas where work was going to be done.

I got myself up on to the roof of the Mart for the job. The Mart is a huge building. It used to be the largest floor space building in the world before the Pentagon was built. It might still be second (and, if I was diligent, I could probably look that up to confirm it but we know that isn’t happening while I am in mid-story). The roof is a big space and there were two separate areas where work was going to be done.

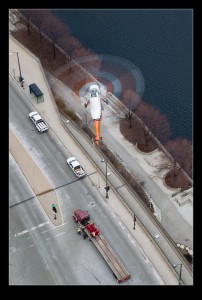

Mounting points on the roof had been installed in advance. The task on the day was to lift each piece of steel to the roof and bolt it into place. The next would follow and the frameworks for mounting the chillers would gradually come into place as the ironworkers bolted each new piece to the previous pieces. (The chillers will follow in a few weeks when Construction Helicopters come to town and I hope to cover that too.) Each pick went pretty quickly. As the new piece came into place, the guys on the roof grabbed it and bolted it into place.

Mounting points on the roof had been installed in advance. The task on the day was to lift each piece of steel to the roof and bolt it into place. The next would follow and the frameworks for mounting the chillers would gradually come into place as the ironworkers bolted each new piece to the previous pieces. (The chillers will follow in a few weeks when Construction Helicopters come to town and I hope to cover that too.) Each pick went pretty quickly. As the new piece came into place, the guys on the roof grabbed it and bolted it into place.

The line would be released and the helicopter would go down for the next piece while the guys finished bolting the piece into place and preparing for the next section. This was a continuous process as long as the helicopter had fuel. Given how warm and sunny it was, the black-painted roof was a hot place to be and the guys were working hard. I was glad to only be photographing the whole thing!

The line would be released and the helicopter would go down for the next piece while the guys finished bolting the piece into place and preparing for the next section. This was a continuous process as long as the helicopter had fuel. Given how warm and sunny it was, the black-painted roof was a hot place to be and the guys were working hard. I was glad to only be photographing the whole thing!

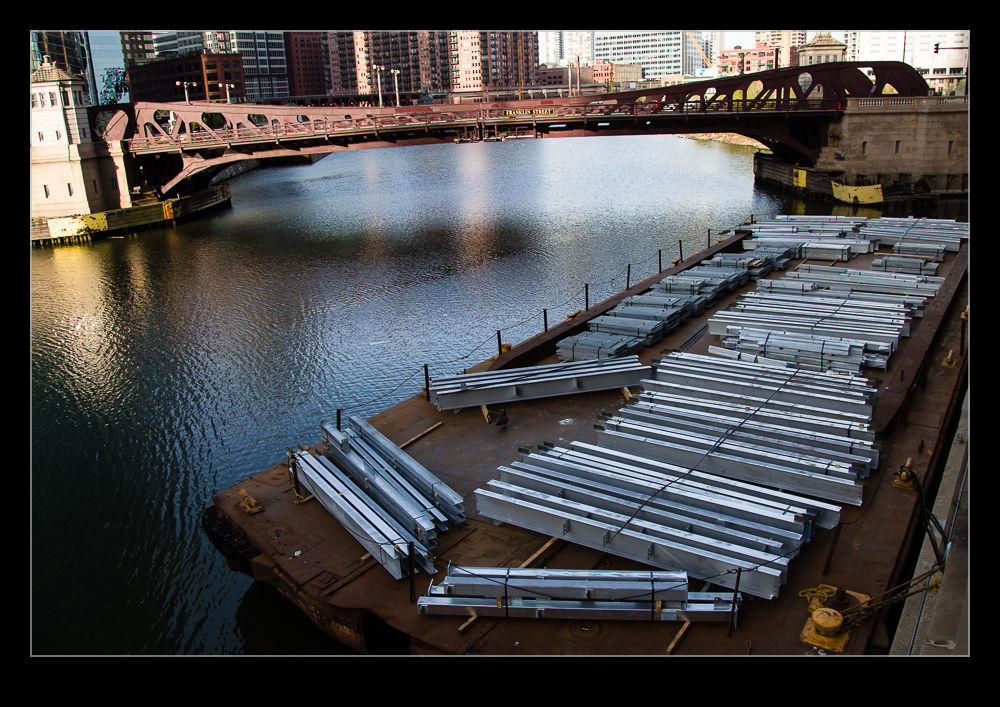

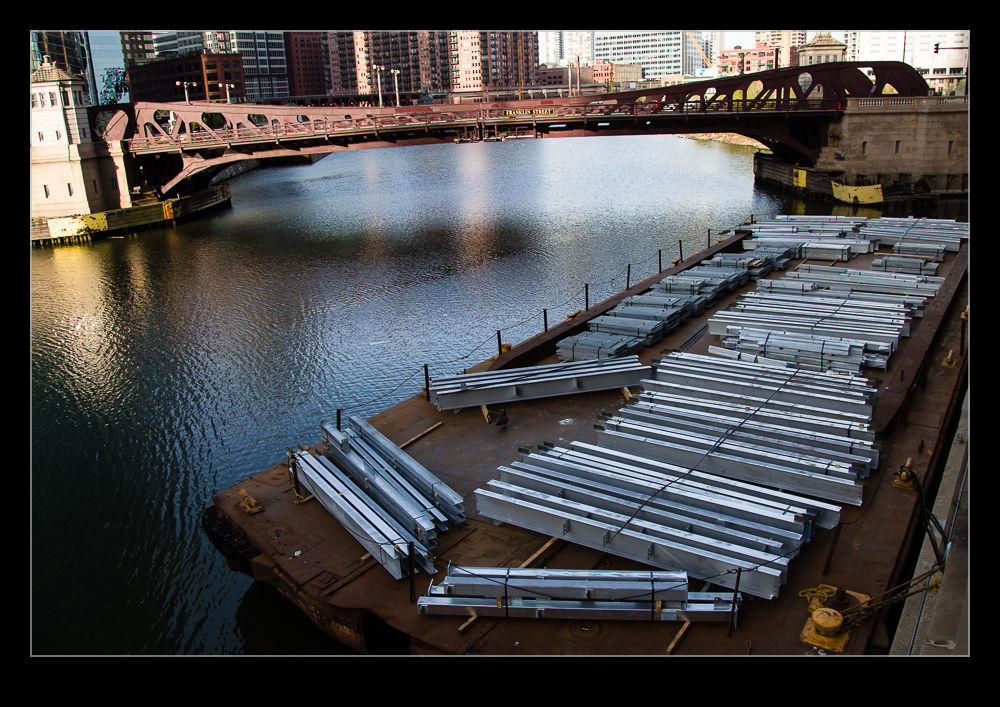

After the helicopter left for the first refueling, I headed down from the roof. I had other things to be done that day and headed off. My original plan had been to get some shots from the ground on the second day. A lot of the steel was being stored on a barge on the river so getting some shots of that being lifted to the roof was the plan.

After the helicopter left for the first refueling, I headed down from the roof. I had other things to be done that day and headed off. My original plan had been to get some shots from the ground on the second day. A lot of the steel was being stored on a barge on the river so getting some shots of that being lifted to the roof was the plan.

However, the team was super-efficient and completed the whole job in the one day. This was a great success for them and, while they were exhausted at the end of it, I am sure they were very pleased with the result. Unfortunately, with no second day, I missed out on getting the other shots I had planned. Oh well, there is always another day.

However, the team was super-efficient and completed the whole job in the one day. This was a great success for them and, while they were exhausted at the end of it, I am sure they were very pleased with the result. Unfortunately, with no second day, I missed out on getting the other shots I had planned. Oh well, there is always another day.

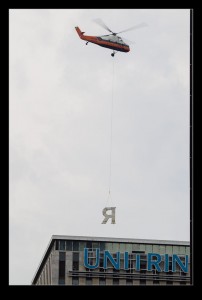

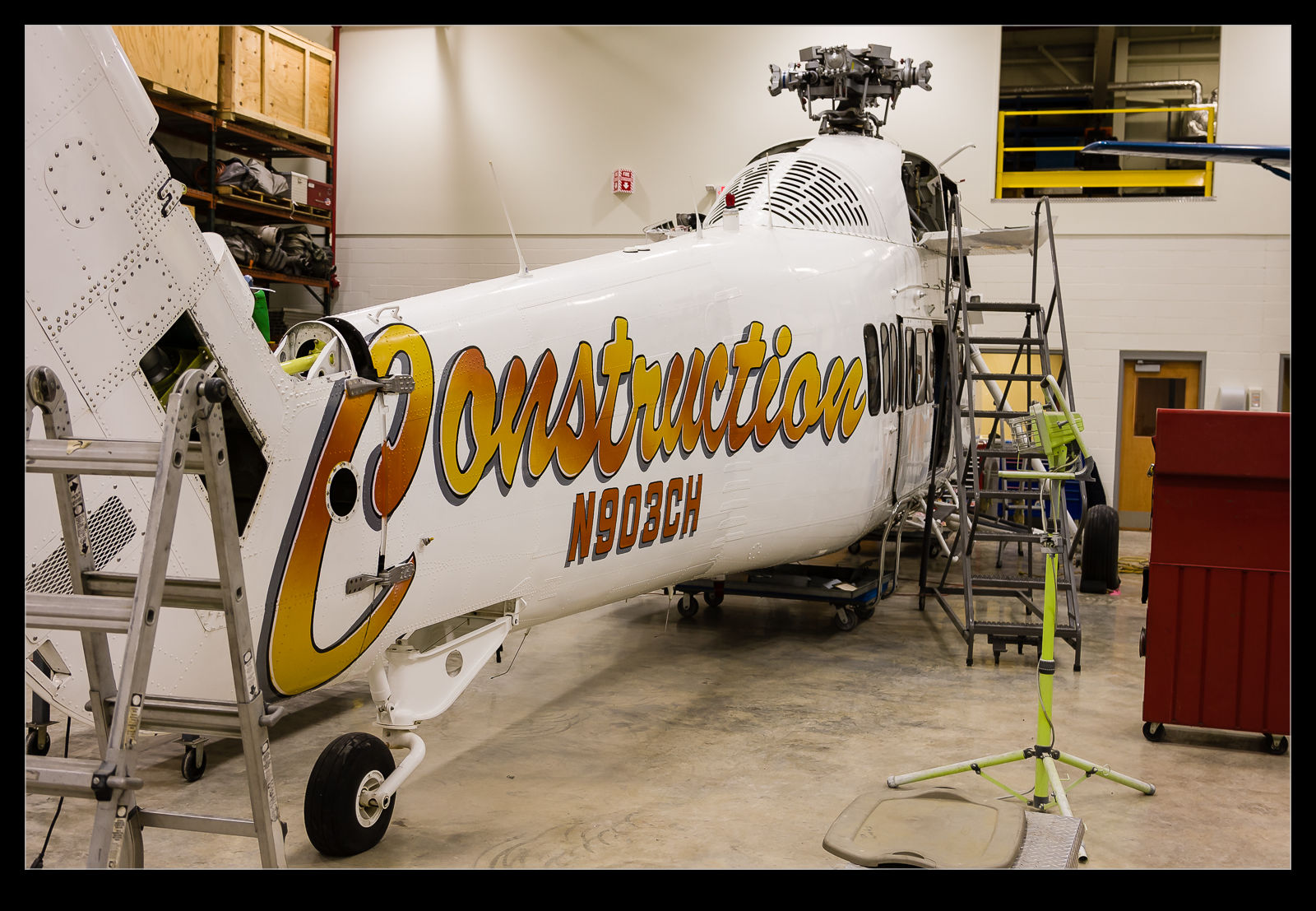

CHI Aviation recently said goodbye to one of their fleets. They posted online a couple of videos of three Sikorsky S-58Ts carrying out a flyby of their Howell MI headquarters before departing. Their fleet covers many types and a lot of airframes and I guess the 58s no longer fulfill a role for them. Consequently, they have gone.

CHI Aviation recently said goodbye to one of their fleets. They posted online a couple of videos of three Sikorsky S-58Ts carrying out a flyby of their Howell MI headquarters before departing. Their fleet covers many types and a lot of airframes and I guess the 58s no longer fulfill a role for them. Consequently, they have gone. I visited Howell a few years back as part of another project I was working on. While I was there, I got a few pictures of the 58s that they had in the hangar at the time. Here are a few of those shots.

I visited Howell a few years back as part of another project I was working on. While I was there, I got a few pictures of the 58s that they had in the hangar at the time. Here are a few of those shots.