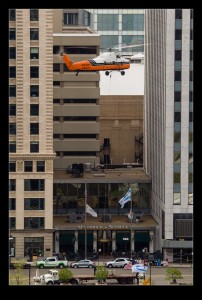

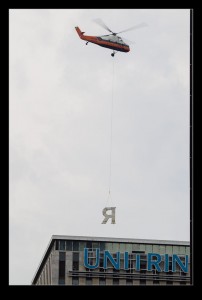

The Thornton Quarry lift job with Midwest Helicopters was a full day job so it provided a bunch of opportunity to try different things. This was true for the stills but it also allowed me to experiment with the video as well. Since the aircraft was operating all day, I was able to get to multiple locations and see all aspects of the job as they happened. Normally, this isn’t possible since a lift will only last about 30 minutes. In that case, you have to pick the location that will get the shots you must have and accept that the alternative shots will not be made.

This time I was able to move around the whole site and capture as much as possible of what was going on. Some of the clips looked really interesting and the time but they actually proved to be no use. Some of the boring stuff as it appeared at the time actually ended up being really of use when it came to editing.

At this point, it is important for me to apologize to people like Gerry Holtz. Gerry is an editor and he does this sort of thing for a living. Anyone else who knows about editing professionally, you are all due my apologies and my respect. I am trying a bit with video editing but what I have learned is that it is bloody difficult to do.

On this shoot, most of the video was captured using my SLR. The rest of it was shot on a GoPro which is such a great little device to get something a little more unusual. It was handheld (or mounted in the case of the GoPro). No tripods or dollies and certainly nothing as impressive as a Kessler Crane!

I suspect that to be good at editing it is important to have had some education in the process. I am doing it the guy way – try something and then try something else and see what happens. Not even a manual to consult! Consequently, I make some progress but probably my approach starts from the wrong place. If I was going to do a lot more of this I would take the training aspect seriously. However, for the time-being, this is a little side hobby so I will probably stick with what I am doing.

Part of the fun(?) of the edit process is taking all of the disparate elements of the footage and trying to combine them into a coherent timeline. Part of the engineer in me thinks it should be delivered in the same order it happened. This is rubbish of course. The viewer has no concern of course. As long as the result doesn’t obviously have terrible jumps or continuity issues, no-one is going to be any the wiser.

Also, how much do they need to see. About eighty lifts were done during the day. Does the video need to have eighty lifts? NO! In the end, I concluded that two lifts were enough to tell the story. One wasn’t enough but it didn’t need more than two. I cut the length down as I went but even then it was still quite a long piece. A pro would probably have it down to a couple of minutes but then, as I mentioned, I am not a video pro.

One lesson I have learned as I have practiced this video stuff is how many of the tools the software has are no use at all. There are a million transitions between scenes, all of which make it look like you are experimenting with the software but they are a distraction from viewing. I have learned to use simple transitions that are short so they are not obvious to the viewer. They just stop the jump being the item the viewer focuses on.

Anyway, the final part of this story is that I was very happy with the result for this video. Unfortunately, it turns out the company that was doing part of the work is very sensitive about their equipment and doesn’t like the equipment being shown on the video so I have had to remove it from my YouTube channel. Consequently, I can’t include it in this post. Oh well…

It wasn’t long ago that I made a trip out to get some shots of the VH-3D helicopters that operate as presidential transports and are known as Marine One when the President is aboard. You can read about that here.

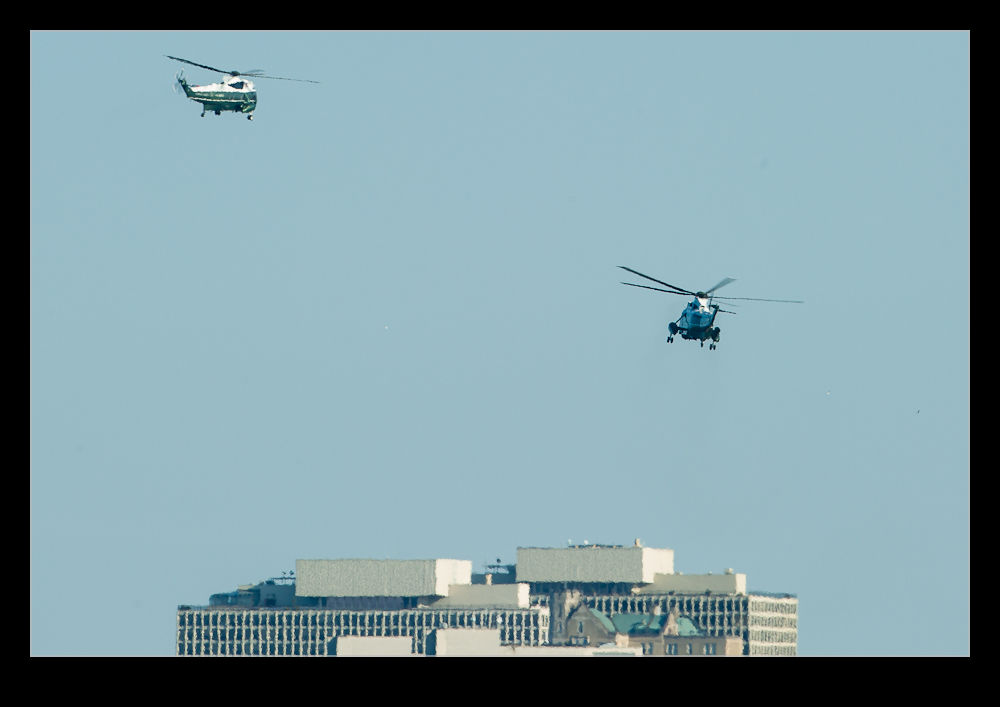

It wasn’t long ago that I made a trip out to get some shots of the VH-3D helicopters that operate as presidential transports and are known as Marine One when the President is aboard. You can read about that here. It turns out I was going to get a second chance. As I drove back up to DuPage airport after shooting Fifi on the approach, I noticed a selection of nice looking helicopters parked up between the hangars. A presidential movement was planned and the aircraft were operating from DuPage. With the TFR being published, we knew they would be heading out early in the afternoon.

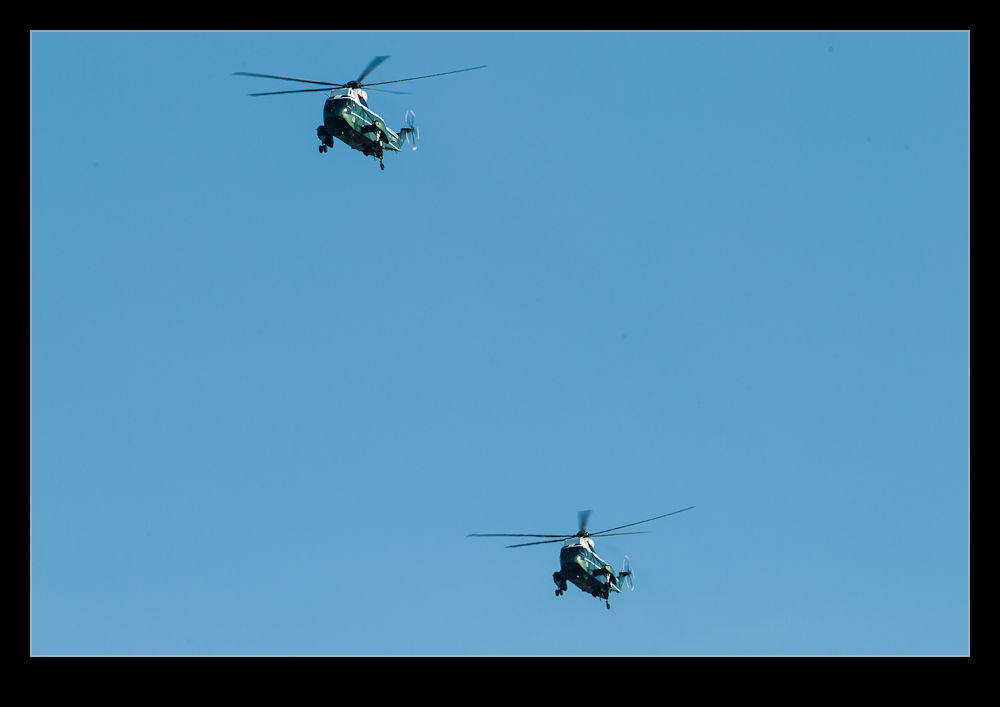

It turns out I was going to get a second chance. As I drove back up to DuPage airport after shooting Fifi on the approach, I noticed a selection of nice looking helicopters parked up between the hangars. A presidential movement was planned and the aircraft were operating from DuPage. With the TFR being published, we knew they would be heading out early in the afternoon. Sure enough, in due course the helicopters came into view. There were the two VH-3Ds along with three CH-46s in support – two of which were in the glossy green finish and one in standard gray. They taxied out in line and lined up on the taxiway. Then they lifted in unison and departed towards the city. It was very cool to watch.

Sure enough, in due course the helicopters came into view. There were the two VH-3Ds along with three CH-46s in support – two of which were in the glossy green finish and one in standard gray. They taxied out in line and lined up on the taxiway. Then they lifted in unison and departed towards the city. It was very cool to watch. A while later I was off the field again shooting Fifi taking off when a couple of the CH-46s came back. I was pretty disappointed to miss their arrival but I got the shot I was there for. When I got back to the field, I was walking across the apron when I met one of the HMX-1 crew-members. I told him how disappointed I was to have missed their return. Not to worry. He told me two more would be back in about ten minutes. Sure enough, in they came. What a great break to get them when I had no idea that they would be there.

A while later I was off the field again shooting Fifi taking off when a couple of the CH-46s came back. I was pretty disappointed to miss their arrival but I got the shot I was there for. When I got back to the field, I was walking across the apron when I met one of the HMX-1 crew-members. I told him how disappointed I was to have missed their return. Not to worry. He told me two more would be back in about ten minutes. Sure enough, in they came. What a great break to get them when I had no idea that they would be there.