I got to climb a tower crane recently. This is something I had never done before and, since it provides a good view of a site and it was a new experience, I was keen to go. I had one of my bigger cameras with me but I didn’t have a strap for it. This proved to be a poor choice. Climbing the ladders to get up the tower is not particularly hard but trying to do so while keeping hold of the hand strap of one camera was possible but very slow.

I got to climb a tower crane recently. This is something I had never done before and, since it provides a good view of a site and it was a new experience, I was keen to go. I had one of my bigger cameras with me but I didn’t have a strap for it. This proved to be a poor choice. Climbing the ladders to get up the tower is not particularly hard but trying to do so while keeping hold of the hand strap of one camera was possible but very slow.

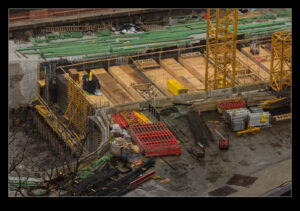

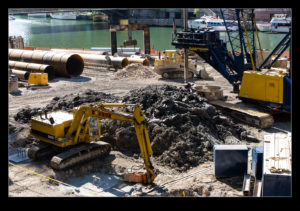

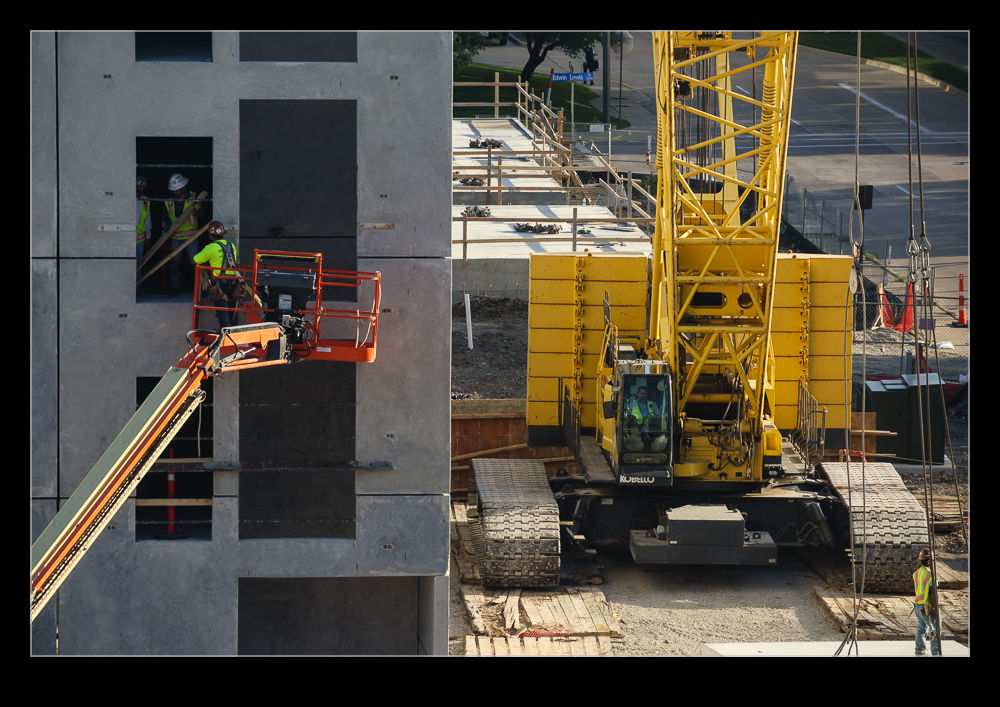

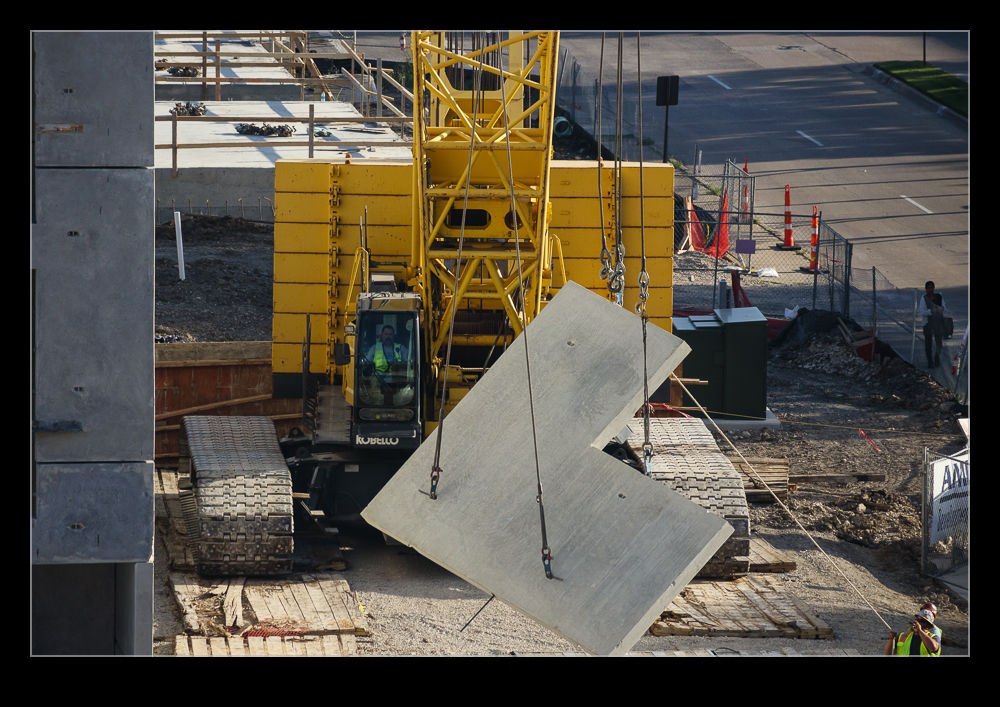

I quickly decided to leave the camera on one of the stage levels and get it on the way back down. It wasn’t like anyone was going to be passing by. I still had my phone in my pocket so that would have to do. I got up to the level just below the cab. Stopping at a few levels on the way up game me some different views of the construction site. An elevated position is so appealing to me. It gives perspective that most people never get to see.

I quickly decided to leave the camera on one of the stage levels and get it on the way back down. It wasn’t like anyone was going to be passing by. I still had my phone in my pocket so that would have to do. I got up to the level just below the cab. Stopping at a few levels on the way up game me some different views of the construction site. An elevated position is so appealing to me. It gives perspective that most people never get to see.

Climbing back down again was a little less easy. There is something about climbing up something which seems more natural than climbing down. However, I was soon reunited with my camera and then finished the last couple of levels. I will take good note of the advice about not bruising your knees as the ladder angle changes. I might have bashed them once or twice. Also, next time I shall make sure to have a strap to allow me to carry the better cameras with me!

Climbing back down again was a little less easy. There is something about climbing up something which seems more natural than climbing down. However, I was soon reunited with my camera and then finished the last couple of levels. I will take good note of the advice about not bruising your knees as the ladder angle changes. I might have bashed them once or twice. Also, next time I shall make sure to have a strap to allow me to carry the better cameras with me!